AI has penetrated every sector, we know that. But one of the greatest evolution conscious of a field is the Artificial Intelligence in the inventory optimization. American retailers have $1.43 on the shelf in the form of inventory for every $1 that they bring from sale. The retail stock is slightly below 1 trillion, roughly 7% of the GDP of the United States.

These numbers emphasize the need for successful inventory management. However, 45% of small-to-medium-sized brands don’t use an inventory management system, leading to inefficiencies and lost sales.

Ai inventory management Solution

With the help of AI, brands are able to forecast the market needs in advance and can adjust their wholesale inventory itself, which leads to the formation of an effective workplace.

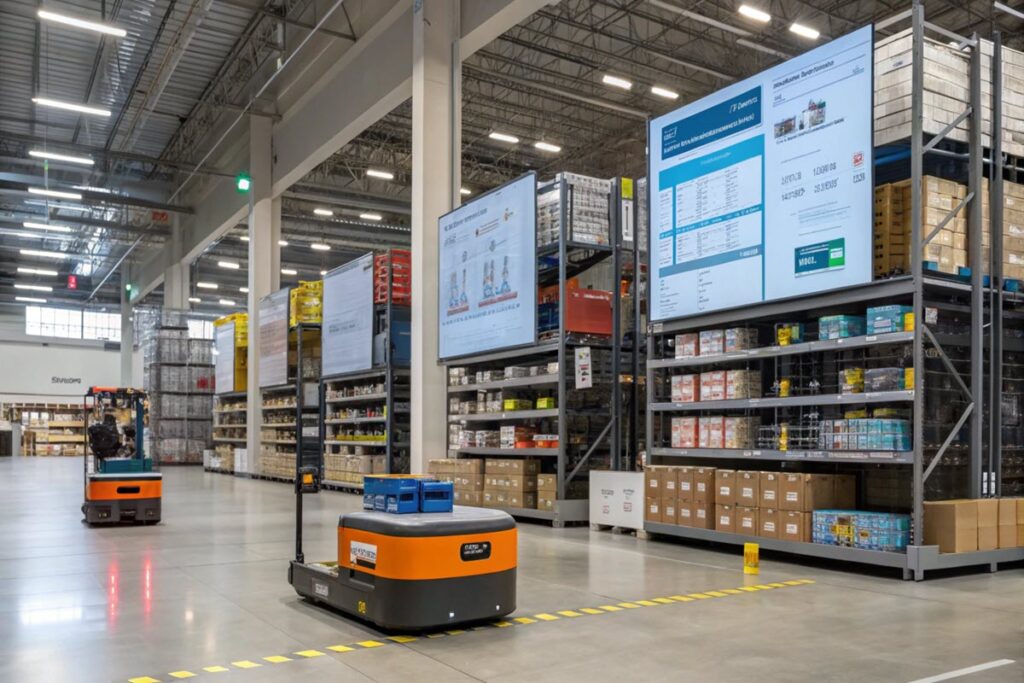

AI-powered systems enable real-time transaction processing of huge volumes of data, thereby helping them to deliver a right demand forecast, bring in more visibility into the supply chain, and automate replenishment. And those capabilities are transforming the world of warehousing and logistics professionals who must stay competitive in a fast development environment.

We shall discuss everything you must be aware of regarding the automation of inventory management through AI in this blog. So, here are all the details without further ado.

What Is AI-Based Inventory Management

This refers to the use of AI technologies to automate inventory management processes and improve inventory control. The process whereby which a company manages and regulates its stock levels, ensuring that the right products are at the right place in the needed time.

Traditional Ai inventory management is enhanced by AI through data analysis, predictive analysis, and machine learning. In ShipTown, this just means automating some of the traditional inventory management tasks such as supplier management, forecasting, and replenishment.

Advantages of AI in Inventory Management

AI in inventory management focuses on better decision-making and efficiency. Some of these advantages are:

Improved Accuracy

Through huge amounts of data, these advanced algorithms are able to analyze and predict demand accurately, in turn eliminating the risk of human errors which may cause overstocking or stock-outs.

Affordable

Because AI can assist with optimizing inventory levels and helping avoid overstocking, they help organizations fill the holes in the supply chain, saving money in storage, holding, and waste costs, Karp said.

Maximized Efficiency

Routine activities, such as tracking inventory and reordering steps, are automated, and staff members are able to redirect their attention to the rest of the operational function.

Growth in Customer Satisfaction

AI-based inventory management solutions ensure that the right products are available at the right time, which enhances customer satisfaction.

Scalability

Organizations can respond rapidly to changing business and inventory needs, allowing brands and businesses to scale their operations without sacrificing efficiency.

Inventory Management across Different Industries with AI

There are also tons of process improvements for inventory management, which makes AI-based solutions applicable to various industries. Many brands use the best inventory management software because they want to benefit maximally from these innovations to be always on the top of a competitive market. This technology, depicted below, is being adopted across different industries.

Retail

Deep learning in the accounting industry: Accounting staff will seek ways to use AI technologies such as computer vision to better organize and plan for stocks, respond to seasonal demand, manage warehouse stocks for better customer experience, and inventory tracking among others. On the other hand, e-payment stores are able to use AI across processes to improve the accuracy of orders and expand the types of products available, simply by analyzing online feedback, user recommendations, and social media trends.

Manufacturing

Manufacturers can use the systems’ efficiencies of AI to forecast production sales, aligning ideal stock levels with demand forecasting. This helps in successful utilization of resources. Electronic inventories are also used for one-off inventory for unlimited amounts of time. This technique allows organizations to procure correctly and ensure that products remain available while reducing carrying costs and wastage.

Distribution and Wholesale

Using AI inventory management processes, wholesalers can organize inventory from different locations. This technology can also help them better manage their extended number of supplier relationships.

Food and Beverage

In the food and beverages industry, companies can use the available trendy technologies to control the products, minimize waste, and serve their customers with new stock. This technology can be used by restaurants to analyze past sales data in addition to changing menus according to the most popular items and market trends. That also aids them in maintaining a sufficient stock of important ingredients.

Medicines Used in Pharma

Artificial intelligence overview for inventory: A conventional inventory method for the clinic is extremely time-consuming. It relieves shortages and enhances the care of patients. Artificial intelligence can be used by drug manufacturers and pharmacies in handling complex inventories while maintaining compliance with regulations and expiry dates.

Construction

Use of AI in inventory management helps construction industries in demand forecast of construction materials. This is speculative based on historical data, project timetable, and matters outside of our control. Also, the best thing is it optimizes the procurement and eliminates delays.

Challenges in AI Inventory Management

Data Issues

Artificial technology can only be as good as the data it is trained on. Bad decisions and predictions could stem from outdated or incorrect or incomplete data. And many times businesses end up with multiple types of data stored in multiple systems resulting in data silos. Integrating these data sources can be complex and time-consuming.

Acceptance to Change

Organizational change in adopting new technologies may not be embraced by employees. Overcoming this challenge requires communication, training, and change management.

Initial Investment

Building AI technology can be cost-prohibitive as well. This includes software purchase, integration, and training. For a smaller brand, this investment may not be a no-brainer.”

Challenges in Security and Compliance

As we have become increasingly reliant on data, data security and privacy are now critical. Similarly, industries would also have to ensure that their inventory-as-a-service powered by AI technology comes in not only under the rules but also keeps private data insulated.

AI’s Role in the Inventory Management Process

Ai inventory management also can aggregate data and automatically classify inventory items based on weight, shape, demand patterns, and so on. It gives you more freedom and organization in writing your work. Automation provides a graphical representation as management and organization methods and the various levels of such management from general to specific work or level, so this accomplishes this, it conducts general inventory management processes.

Insights from Inventory Management Data

Let me start with a few interesting points that make us understand how AI is revolutionizing the inventory management process.

It is capable of automating manual tracking protocols through barcode integration, scanning, and sensors.

Demand planning systems use demand forecasting algorithms and predictive analytics to do capacity planning and more innovative procurement.

Common Algorithms for Inventory Management

The following are the two most common inventory tracking algorithms:

- FIFO (First in, first out)

- LIFO (Last in, first out)

FIFO processes and sorts the topside and pre-extracted so that the inventory can be received and sold in order. LIFO indicates that we sold/accepted the items in the inventory in reverse chronological order.

The Final Notes

In brief, AI in inventory management is a boon for warehouse or logistics owners. Now, leveraging the power of AI, a brand can achieve efficiency, savings, and accuracy. We are already witnessing many benefits of AI, including improved forecasting accuracy, better warehouse efficiency, enhanced visibility into the supply chain, and automated replenishment. Even further with tech advancements, AI’s role will be significant in inventory management with more room for successful innovation.